What's the difference between Digital Dentures vs. Traditional Dentures?

Unlike traditional denutres, digtial dentures use advanced technology to streamline the design & manufacturing of prosthetic teeth.

Digital dentures combine state of the art CAD/CAM design, intraoral scanning, and 3D printing to streamline the denture process while improving fit and comfort. Thanks to digitla workflows, we can reduce the number of appointments, minimize adjustments, and store the patient’s design for future remakes. At ODL, we fabricate every component in house, allowing us to maintain tight quality control and customize aesthetics, all while enabling faster turnarounds.

Our Digital Denture Products

Premium Denture

The Premium Denture is fabricated by an injection heat cured method using Ivoclar IvoBase/Ivocap® which aids in consistent polymerization. More characterization is added to the denture by festooning and stippling. Kulzer Mondial teeth are used.

Economy Denture

The Economy Denture is a cost effective denture fabricated by

a cold curing process using Ivoclar ProBase® Cold. This denture

has a smooth surface and minimal characterization. Classic® teeth are used.

Immediate Denture

Flexi Partial Denture

Our partial is printing using Cabon’s FP3D material, which is engineered for durability and low water absorption, helping maintain its shape and color over time.

The Benefits

A digital workflow reshapes how dentures are created from start to finish. Here are the advantages that make this approach stand out.

Enhanced Precision & Fit

Fewer Patient Appointments

Accelerated Production Time

Improved Durability

Simplified Replacement and Remake Process

Customization & Aesthetics

Smile Design Previews

Improved Lab & Patient Communication

Great Comfort & Stability

What Patients Can Have Digital Dentures?

Existing Denture Patient

Existing Denture Patient

Patients with an existing denure that fits well, or at least provides a good esthetic and funcional baseline.

We can scan the current denture, duplicate its positive feautres, and digitally correct problem areas. This enables faster turnaround, fewer appointments, and predictable results.

Immediant Denture Patient

Immediant Denture Patient

For patients who still have teeth but require full extrations.

We us pre-extraction scans (IOS or model scans) to digitally design the immediate denture in advance. After extractions, the patient leaves with their prosthesis the same day, and we can easily adapt the digital file later for relines or a definitive denture.

Edentulous Denture Patient

Edentulous Denture Patient

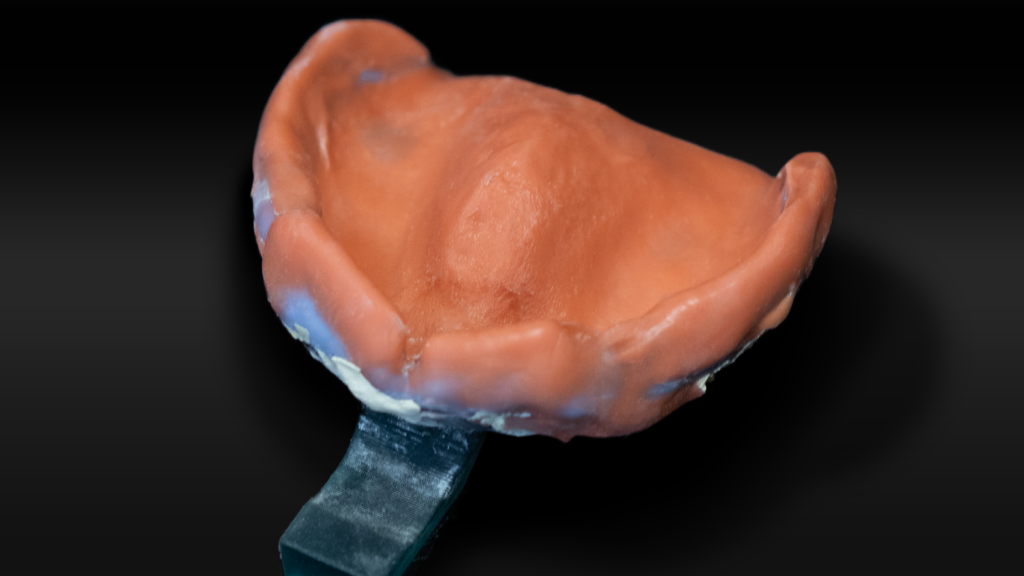

Ideal for patients with no remaining teeth who need a traditioal full upper and or lower denture.

Digital workflows allow us to capture impressions, jaw relations, and esthetics quickly using IOS or traditional impressions that we digitize, then design and print the final prosthesis with improved fit and predictability.

Our Digital Denture Workflow

Our team handles every stage of the digital denture process in house, ensuring quality from start to finish. With full control over the process, we’re able to deliver consistent fit, natural esthetic’s, and predictable outcomes from both full arch and partial cases.

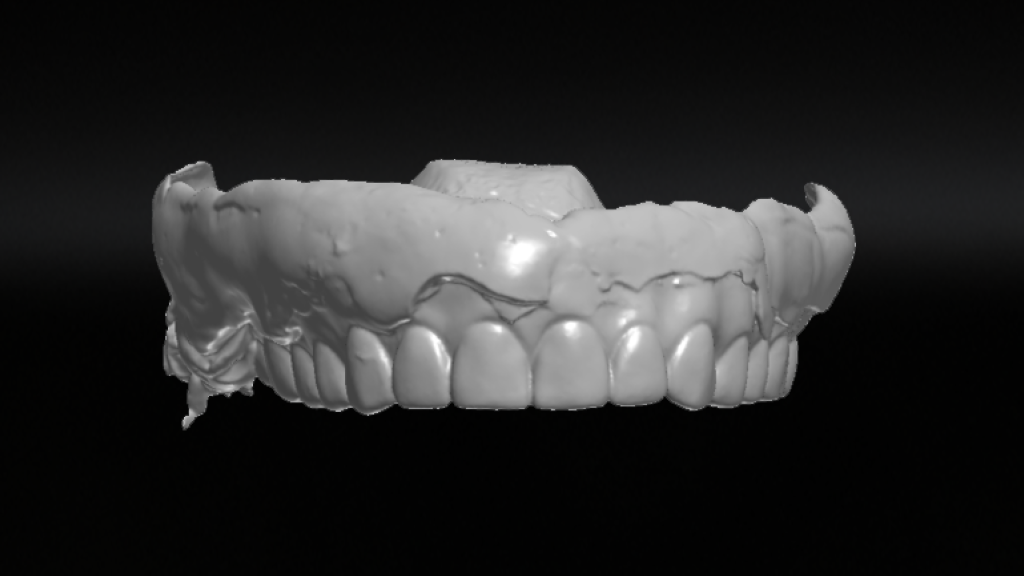

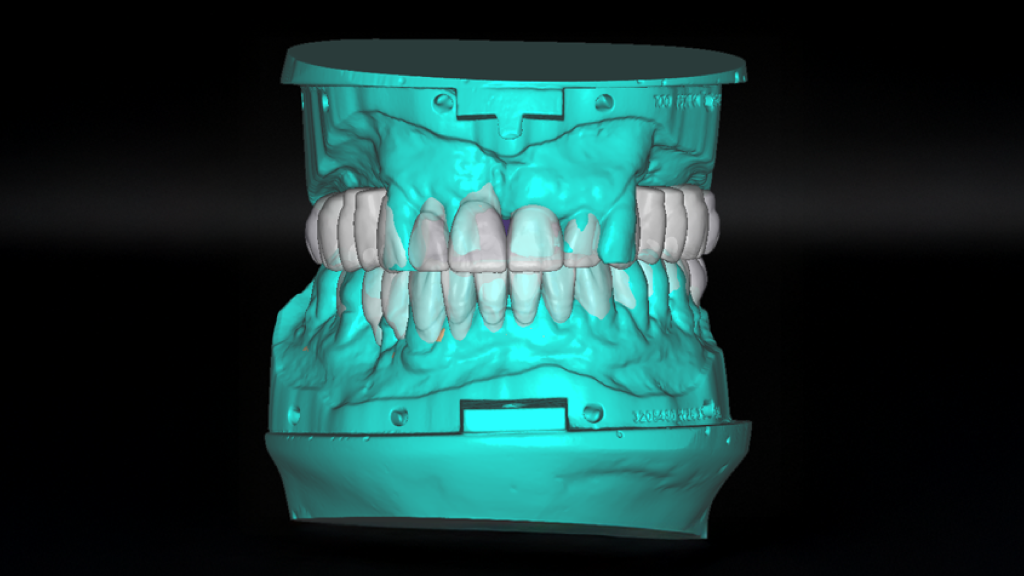

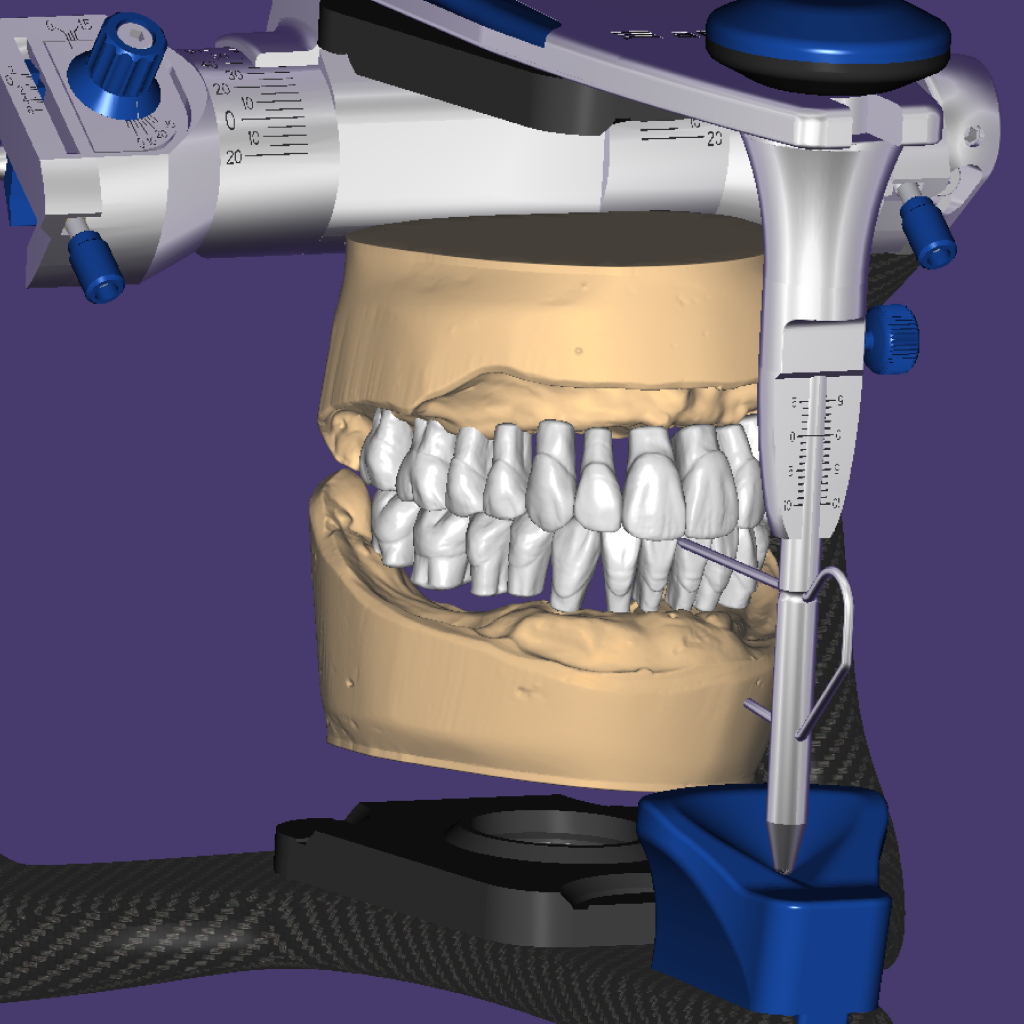

Scanning & Design

Using a captured intraoral data (IOS) or scan mailed impressions, ODL imports the files into the CAD software and sets up the case. The scan helps us design the denture base and teeth.

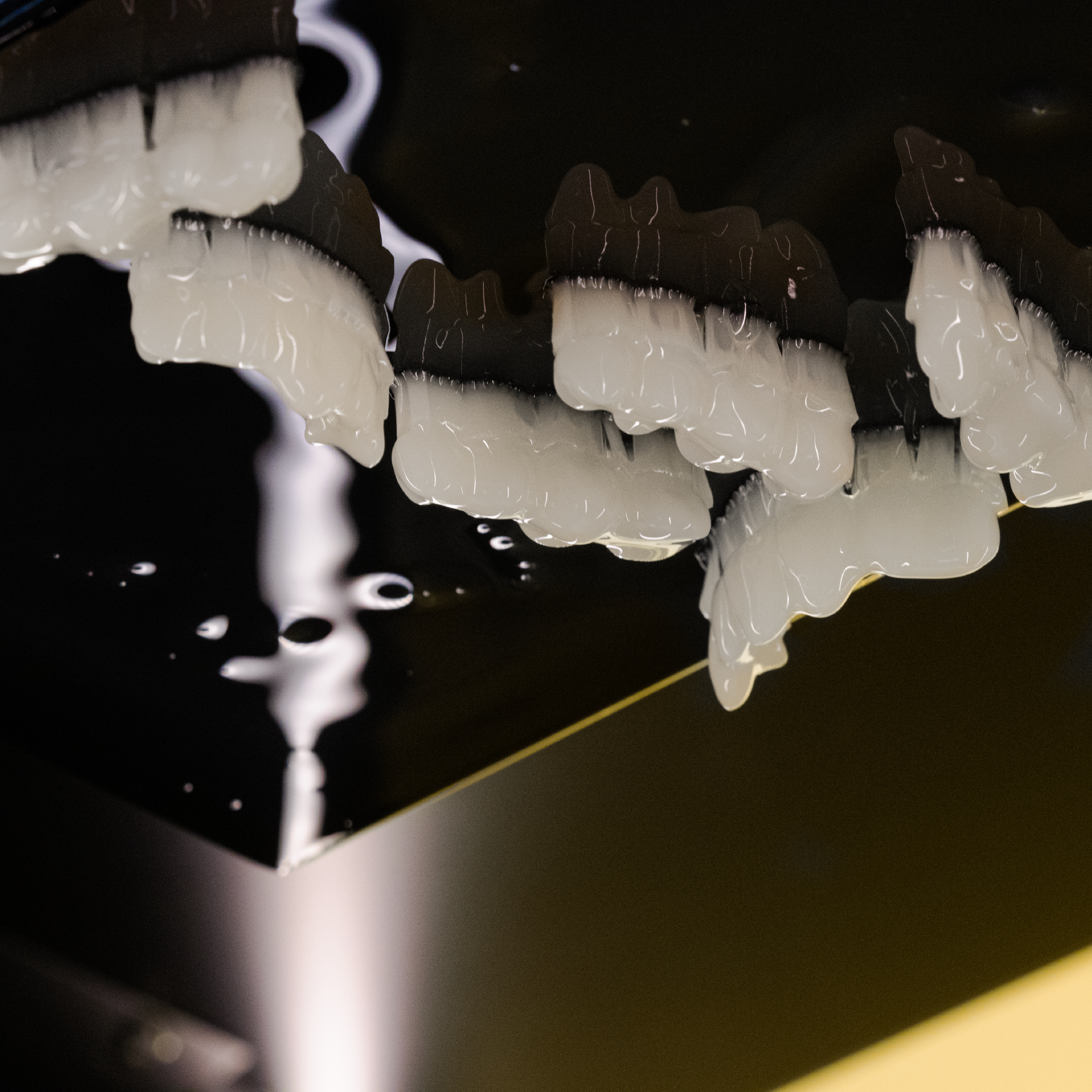

3D Printing

Our 3D printers print monolithic/integrated base and teeth, which will be later assembled. Once printed, the individual components are removed from the building platform, washed, and inspected.

Bonding & Curing

A small amount of liquid resin is painted into the pockets of the base and bonds the teeth to the base of the denture using a UV light cure. Some teeth are placed individually or in sets/rows to improve adhesion.

Finishing

Once the teeth are bonded, a scraping pick is used to trimming excess material, scraping, and contouring the margins as needed.

Final Cure

A final cure is used to ensure maxium strength. This process typically takes a few hours.

Sanding & Filing

Remove the supports, trim excess material, scrape flash contour margins, and adjust occlusion contacts as needed.

Polishing

The dentures are polished to a high gloss using pumice, polishing pastes, brushes, and rubber wheels. Edges are rounded and occlusion is finalized.

Blow Dry & Final Looks

A final air-dry/blow dry to remove debris and inspection on shade, surface finish, and occlusion is performed before packaged and shipped to your office.

Interested In Digital Dentures?

Talk to our team about getting your patients a set of digital dentures!

Digital workflows reduce the number of appointments, minimize chair time, and simplify communication between the practice and the lab. The result is a smoother process from initial records to final delivery, with designs that can be stored and easily replicated when needed.